Paul Shepherd

Industrial Robotics Consultancy Ltd

Tel: +44 (0) 7760 488738

Registered Company for England and Wales No: 11983172

© 2019 Industrial Robotics Consultancy Ltd

Industrial Robotics Consultancy Ltd

Industrial Robotics Consultancy Ltd has been established with one fixed goal.

’Helping to bridge the gap between OEM and integration’

Although OEM’s and System Integrators are pushing the boundaries of technology and applications; developing new products, features and functions to lean towards an ‘out of the box experience’.

There is and continues to be a distinctive gap between what is stated in product manuals, system technical documents and what happens in reality.

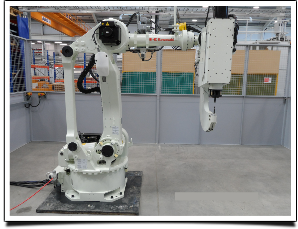

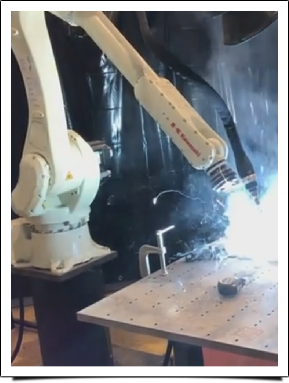

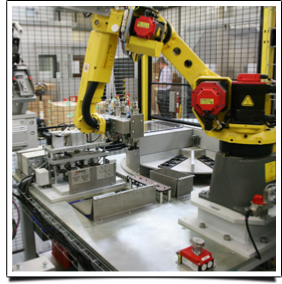

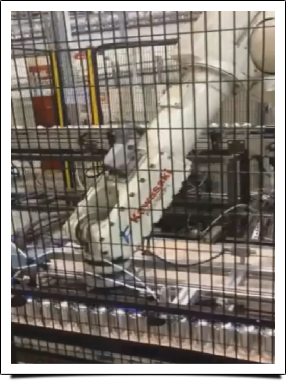

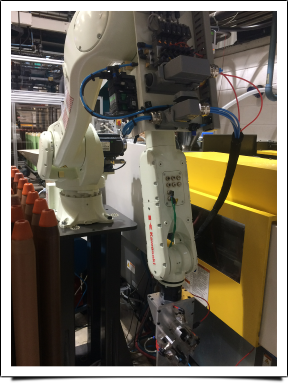

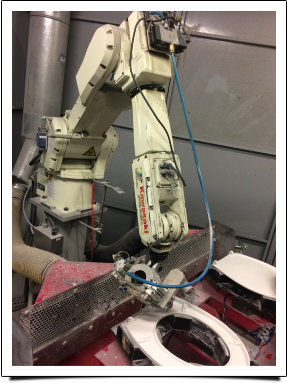

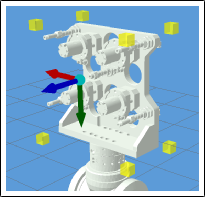

Industrial Robots have a very generic function, a manipulator, a tool, an entity to remove the human element of an application to improve efficiency and therefore improve productivity.

Many applications consist of a ‘tailored’ element, which means there are no google answers to address issues, there may be you tube guides up to a certain degree, but unless someone has experienced or documented it, then finding the correct resource could take valuable time.

Drawing on over 20 years of experience within Automated Manufacturing.

Involvement with major OEM’s, product assembly, testing and fault finding.

Commissioning, site support, training and customer interfacing.

Industrial Robotics Consultancy Ltd has been established to provide training, technical support and a reliable source of information and assistance when needed.

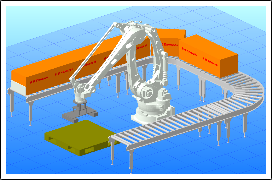

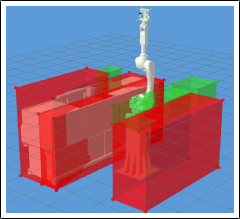

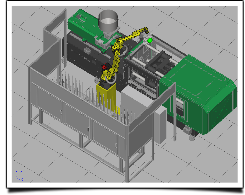

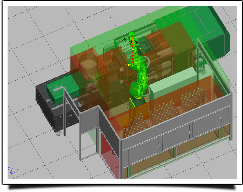

Industrial Robotics and Cell Integration

Automated cells containing a robotic solution offer some interesting challenges and

steep learning curves.

Have you found yourself in any of the following situations:

- Personnel do not have full confidence in operation and maintaining the equipment.

- Key personnel leave, taking with them valuable knowledge and documentation.

- Training new staff without guides and documentation.

- OEM's can be reluctant to undertake training, especially on dated equipment.

- System Integrators have not provided suitable training for your personnel.

- Training documentation is inaccurate or incomplete.

- Complete reliance on System Integrator product knowledge.